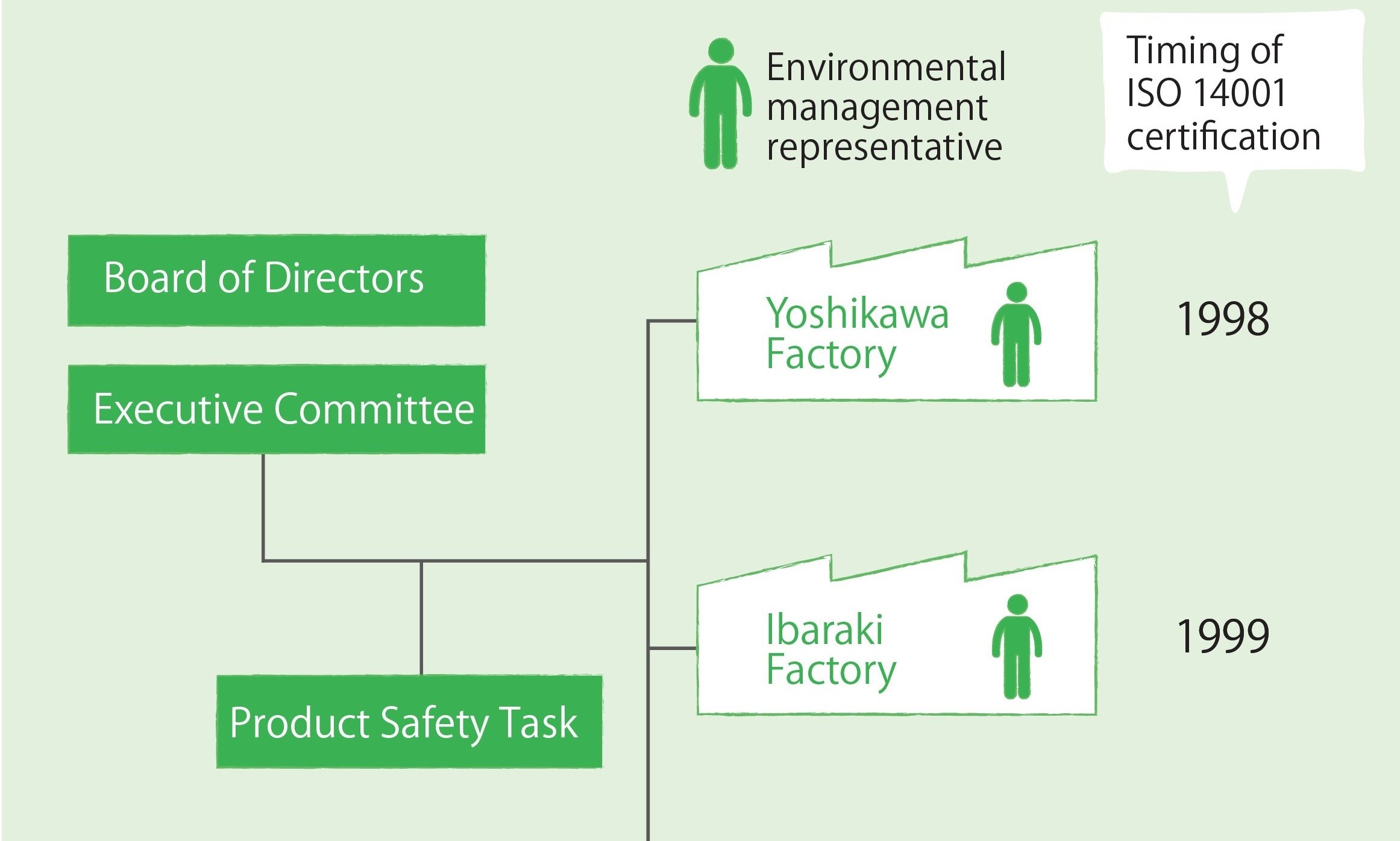

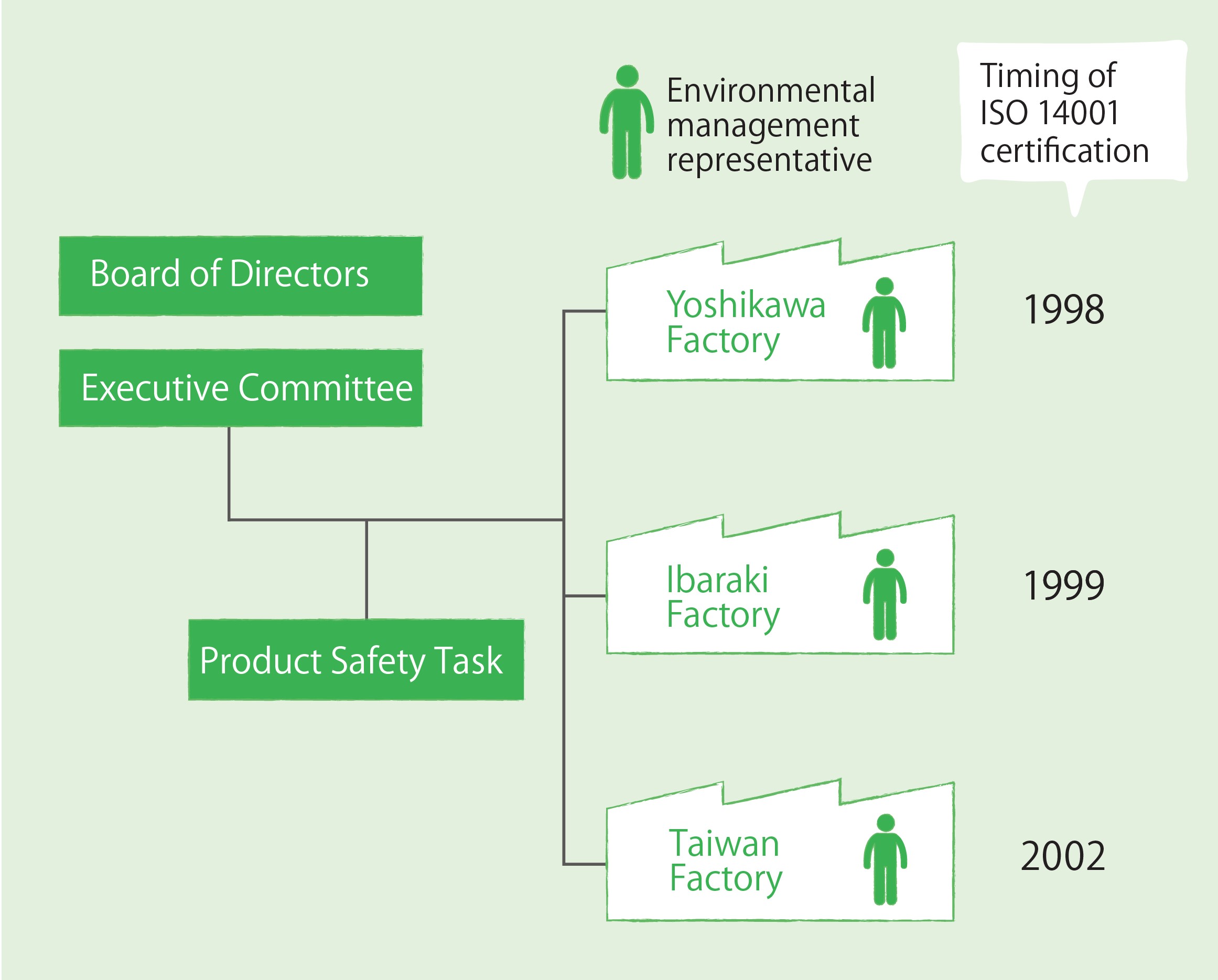

Based on the Basic Philosophy of the Environmental Principles, we have built an environmental management framework, which is aimed at developing and operating environmental management systems, to make our activities at factories and offices even more environmentally conscious and effective for environmental conservation. ISO 14001~{*1} certification the Yoshikawa Factory in 1998, the Ibaraki Factory in 1999, followed by the Taiwan Factory in 2002, and these factories steadfastly continue to make improvements in their environmental performance.

- 拡大

- Environmental management framework

*1 ISO 14001

A set of standards for the development of an environmental management system designed to continuously improve environmental performance of corporate activities, products, and services (including the reduction of their impact on the environment).

We provide all employees with environmental training, which is aimed at improving their basic knowledge of the environment and raising their awareness of environmental conservation. In addition, we provide leaders of environmental activities with training on relevant laws and regulations and specialized technologies, skills training and training to qualify them as internal environmental auditors.

The environmental management representative of each factory and internal environmental auditors check that all business activities conducted at their respective sites are in compliance with the ISO 14001 standard and the company’s environmental management system. They also use these audits as an opportunity to hear proposals from every division regarding on-going improvements of the environmental activities conducted at each site. The company also employs a bottom-up approach in its efforts to improve the environment by encouraging every employee to take part through quality control (QC) circle activities such as environmental improvement planning and “wall newspaper” contests.