|

Company Name |

Pentel Co., Ltd. |

|

Head Office |

7-2 Koami-cho, Nihonbashi, Chuo-ku, Tokyo 103-8538, Japan |

|

Established |

March 1946 |

|

Capital |

450 million yen |

|

Business |

Manufacture and sale of stationery and office supplies (drawing and painting materials, writing instruments, etc.) Manufacture and sale of electronic devices (touch panels, touch switches, pen tablets, etc.) Manufacture and sale of industrial robots, industrial automated assembly machines, injection molding precision molds, and precision hand presses Manufacture and sale of chemical-related products (cosmetic parts, medical instruments, etc.) |

|

Number of Employees |

2,648 (FY2024/Consolidated) 734 (FY2024/Non-consolidated) |

|

Sales |

46,200 million yen (FY2024/Consolidated) 23,325 million yen (FY2024/Non-consolidated) |

※As of September 2022

●:Sales Office ●:Factory

Pentel manufactures and sells stationery and office supplies including drawing and painting materials, erasers, marking pens, ballpoint pens, mechanical pencils, and refill leads.

Based on the conviction that “We develop original things and create new demand and markets,” we have launched pioneering and revolutionary writing instruments including the world’s first ever “synthetic resin mechanical pencil leads,” the Pentel Sign Pen, which became a global hit after being used by the President of the United States of America, and the “Pentel Brush” pen made with artificial hairs.

Inheriting the sense of adventure and creative spirit that have been our inspiration since the company’s founding, we will continue to supply products that are loved by our customers.

Having developed “analog inputting tools” such as crayons and ballpoint pens, Pentel is also developing and manufacturing “digital inputting tools” based on control technology we have nurtured in the production equipment arm of our stationery business.

Leveraging our core technology of electrostatic capacitance coupling, we have developed liquid crystal pen tablets for writing and drawing characters and pictures on liquid crystal screens. In particular, our pen tablets used for writing on photo sticker machines have maintained a high share for many years.

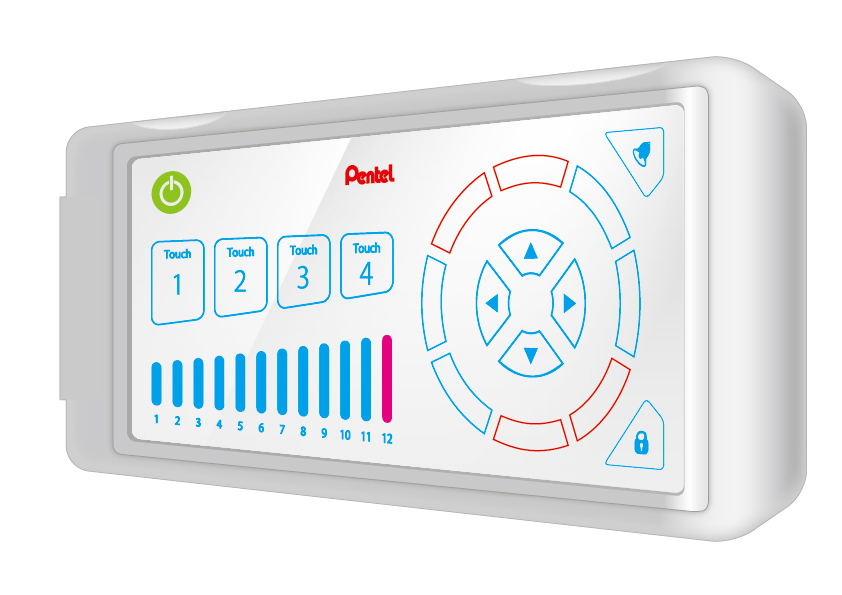

Also, our stable operation electrostatic switches are widely used in electronic appliances, operating panels and the like. We will continue to develop accessible and easy to use inputting devices that facilitate users’ dreams.

Liquid crystal pen tablet

Capacitive touch screen switch

Leveraging Pentel’s technology and know-how that have been nurtured in the research and development and production of stationery, our chemical business has developed with the objective of receiving orders from various manufacturers to develop and manufacture products.

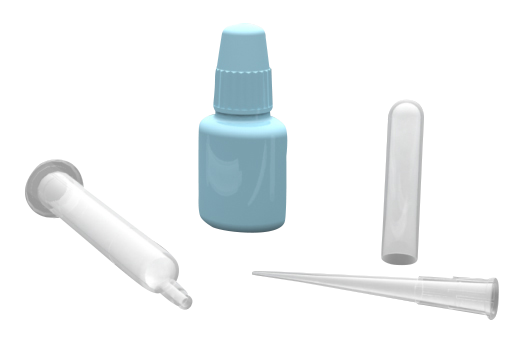

Our pen-type cosmetic applicators, which utilize Pentel’s strengths of pen mechanisms and touch, have earned the trust of cosmetic makers around the world. We leverage our world-class nylon hair processing technology to support the development of cosmetic brushes and other products.

We supply products that leverage Pentel’s technology in the medical field too.

Undertaking all operations from the mechanism design of products to commercialization and mass production, we supply safe medical components and containers that clear strict quality criteria. In this way, we support our customers in developing outstanding products.

Cosmetics containers

Medical components

Based on the policy of “making the company’s products with the company’s own equipment,” Pentel was the first stationery manufacturer to automate its production lines, thereby realizing major improvement in productivity.

We launched our machine business by leveraging our extensive track record in not only designing and developing products but also production equipment.

Currently, we not only manufacture in-company equipment for manufacturing stationery, but we widely deploy industrial production equipment for other companies.

Concerning our automatic assembly machines for assembling and inspecting components, automated insert injection systems equipped with our proprietary industrial robots, image inspection systems and other products, we have earned high praise and trust from customers for functionality and ease of use.

So far, we have developed and manufactured approximately 2,000 production systems for use in a wide range of industries such as automobile parts and medical care.

Scara (Selective Compliance Assembly Robot Arm)